Toyota’s Canadian operations have introduced seven humanoid robots into SUV production lines, marking a visible step toward more flexible industrial automation.

While automotive plants have long relied on robotic arms for welding and painting, humanoid robots represent a different approach — designed to navigate environments built for human workers.

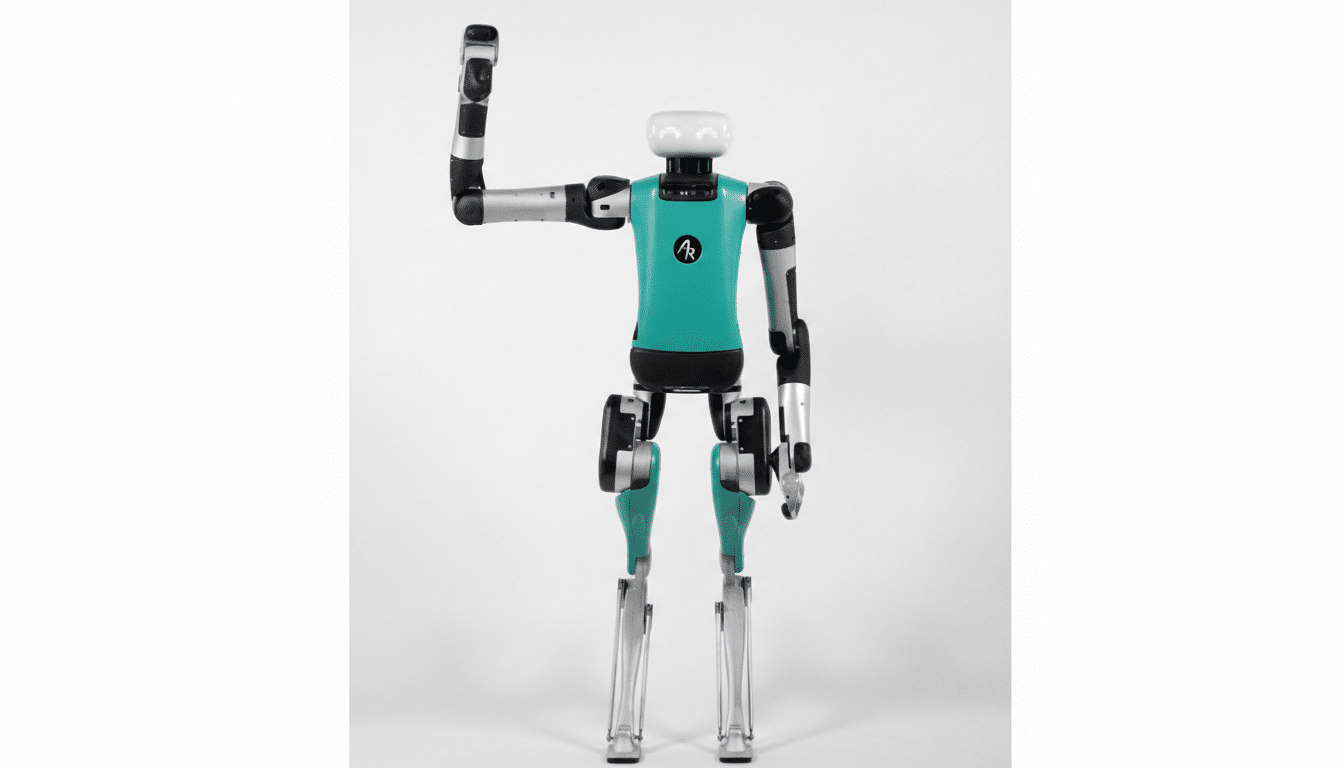

Why Humanoid Robots?

Traditional industrial robots excel at repetitive, fixed-position tasks. Humanoid robots aim to handle more variable activities, including parts handling, inspection, and assembly support.

Because they resemble human form factors, they can potentially operate in existing factory layouts without extensive redesign.

For manufacturers, this flexibility reduces the need for entirely new infrastructure.

Toyota has historically invested in robotics research, including assistive technologies and automation systems designed to complement human workers.

Addressing Labor and Efficiency Pressures

Automakers globally face labor shortages, rising wage costs, and pressure to increase production efficiency.

Deploying humanoid robots can serve several strategic goals:

- Supporting repetitive or ergonomically challenging tasks

- Improving workplace safety

- Maintaining production continuity during labor shortages

- Increasing precision in assembly processes

In high-volume SUV production, even small efficiency gains can translate into substantial cost savings.

Automation in the EV Era

The automotive sector is undergoing transformation driven by electrification and software integration.

Production lines must adapt to new vehicle architectures, battery modules, and electronic systems.

Humanoid robots may offer greater adaptability compared to fixed automation systems, allowing manufacturers to reconfigure production with less disruption.

For North American facilities competing globally, advanced automation can improve competitiveness and output reliability.

Human-Robot Collaboration

Toyota’s deployment appears designed to complement rather than replace human workers.

Collaborative robotics — often referred to as “cobots” — focuses on safe interaction between machines and employees.

Regulatory and safety standards require careful integration to ensure that robotic systems operate within defined safety parameters.

The long-term success of humanoid robots in factories will depend on reliability, cost-effectiveness, and seamless human collaboration.

Broader Industry Implications

Robotics firms have accelerated development of humanoid systems in recent years, driven by advances in AI vision, motion planning, and sensor integration.

Automotive manufacturers are natural early adopters due to structured environments and scale economics.

If Toyota’s deployment proves operationally effective, other manufacturers may expand pilot programs into broader production networks.

For robotics startups and AI companies, large industrial contracts offer validation and revenue pathways beyond consumer robotics.

A Measured Step Toward Automation’s Next Phase

Seven robots do not transform a factory overnight. But symbolically, their presence signals a shift.

Humanoid robotics is moving beyond demonstration projects toward industrial deployment.

As manufacturing adapts to digital transformation and labor constraints, flexible automation may define the next chapter in automotive production — and Canada’s Toyota facilities are now part of that experiment.

![[CITYPNG.COM]White Google Play PlayStore Logo – 1500×1500](https://startupnews.fyi/wp-content/uploads/2025/08/CITYPNG.COMWhite-Google-Play-PlayStore-Logo-1500x1500-1-630x630.png)