Ever wonder how Apple tests its iPhones for dust, water, drop protection, and more? Apple invited MKBHD to check out its special laboratories with custom machines for durability testing as well as talk with Apple’s chief of hardware John Ternus. Check out the fascinating Apple lab footage to see how it all works.

MKBHD shared multiple short videos on X this morning showing the neat behind-the-scenes look at how Apple tests its IP (dust/water) ratings, drop resistance, vibration resistance, and more.

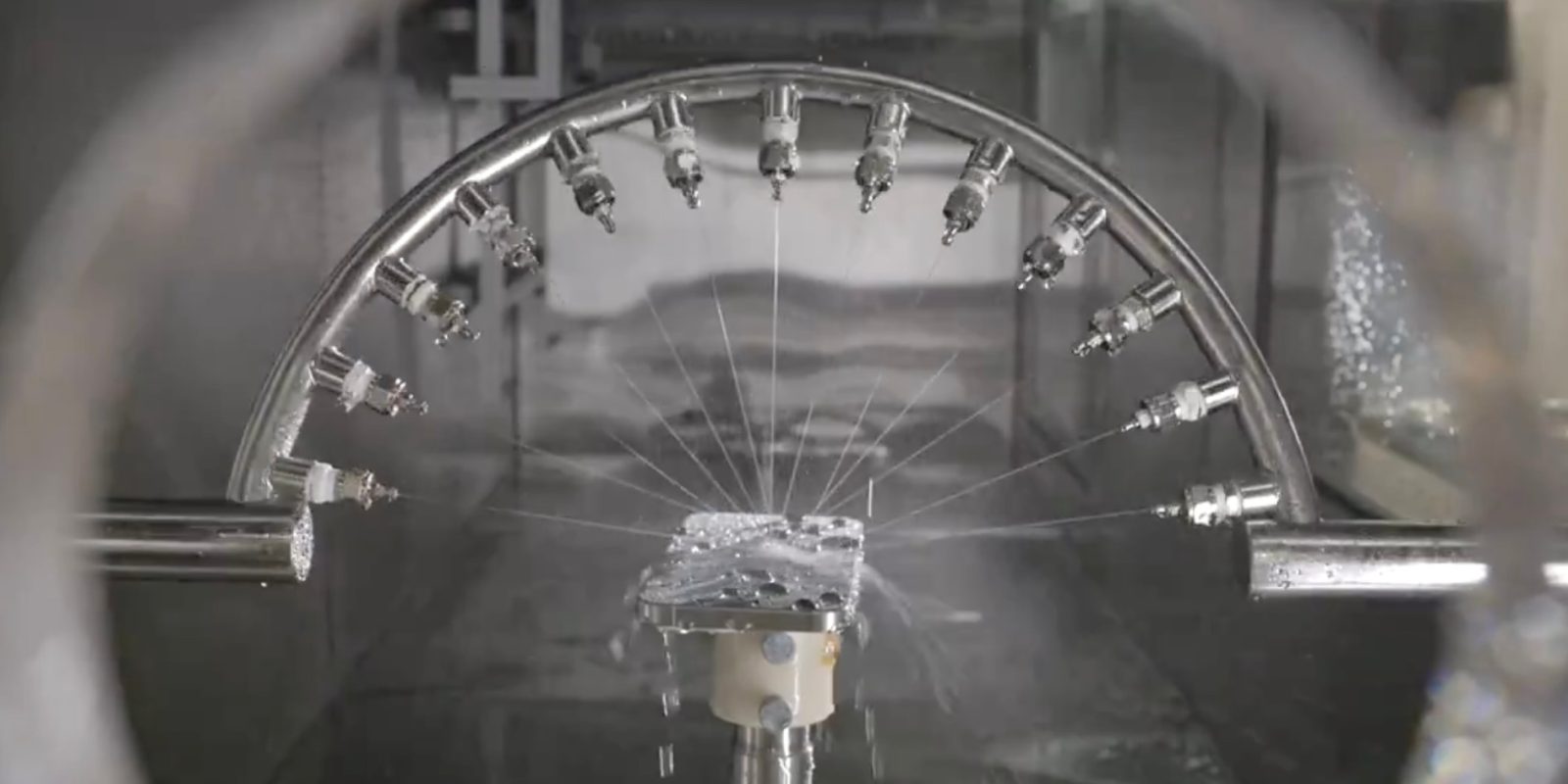

In typical Apple fashion, the labs have extremely detailed machines to thoroughly test each metric.

For example, one of the water ingress tests uses 13 streams of water while it rotates almost 360 degrees, hitting iPhone from all angles.

MKBHD notes there’s an entire room dedicated to just water/dust ingress. And for water alone, there are four levels that Apple tests at:

- Drip tray simulation

- Sustained, low-pressure jet spray

- High-pressure spray from a “literal firehose”

- Locking the phone underwater plus extra pressure to mimic depth for an extended time

Another interesting tidbit is Apple sometimes tests up to 10,000+ pre-release iPhones for durability.

The behind-the-scenes footage also shows the drop-testing system, vibration-testing system, and a short interview with Apple’s John Ternus discussing repairability, durability testing, and more.

Check it all out in the full thread here:

Top image by MKBHD

FTC: We use income earning auto affiliate links. More.

![MKBHD shares behind-the-scenes look at Apple’s iPhone durability testing [Video] MKBHD shares behind-the-scenes look at Apple’s iPhone durability testing [Video]](https://i0.wp.com/9to5mac.com/wp-content/uploads/sites/6/2024/05/apple-durability-test-behind-the-scenes.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![[CITYPNG.COM]White Google Play PlayStore Logo – 1500×1500](https://startupnews.fyi/wp-content/uploads/2025/08/CITYPNG.COMWhite-Google-Play-PlayStore-Logo-1500x1500-1-630x630.png)