In June 2024, Airbus’ shares tumbled nearly 10% as the world’s largest aircraft manufacturer cut its profit forecast. The reason? Airbus blames persistent parts shortages that impact productivity and push back schedules.

The global supply chain is not as robust as one assumes. In September 2023, Jet engine maker CFM International accused a UK distributor of selling thousands of falsely certified components. In an era of groundbreaking innovations when fully electric, vertical-takeoff-and-landing machines are ready to take to the skies, leading manufacturers are still facing turbulence regarding a steady supply of top-quality aircraft components.

Closer home, there is a growing reliance on a host of startups such as Agnikul, Big Bang Boom Solutions, Skye Air and more, specialising in aerospace and defence (A&D), remote sensing, spacetech, and other deeptech areas. At a time when the Indian government has been bullish on Make in India and Vocal for Local initiatives, these tech-focussed young companies are leveraging every possible advantage coming their way to tackle the most pressing local and global challenges, be it sophisticated security systems, climate change, green mobility or sustainable energy.

Udaan Of A Different Kind Charted By Jeh Aerospace

As entrepreneurs increasingly explored uncharted territories, two veterans from aerospace manufacturing saw an opportunity to embark on a bold new course. Venkatesh Mudragalla, former head of programme management and operations at Tata Sikorsky Aerospace, and Vishal Sanghavi, former COO of Tata Boeing Aerospace, eventually parted ways with the Tata group and launched Jeh Aerospace, India’s very first startup dedicated to aerospace and defence manufacturing. Between them, the founders had nearly three decades of experience, no doubt a plus for planning a new venture and creating goals based on in-depth industry insights.

The year was 2022, when most industries were still grappling with the Covid-19 aftermath, and manufacturers struggled to recall their workforce and resume operations. But soon enough, the founders realised that the challenge went far beyond pandemic-related disruptions. In essence, aerospace manufacturing has been constantly plagued by supply constraints stemming from the fragmented nature of the business, lack of innovation and tepid investor interest in a capital-intensive industry dominated by MNCs and government players.

One way out could have been setting up Jeh as a supply-chain enabler, a managed marketplace connecting aircraft builders with component manufacturers who have the right delivery capabilities.

But after carefully analysing the ground conditions, the duo gauged that such a business model might not be sustainable in the long run. The industry required (and still does, given the headwinds faced by Airbus) trusted, global-standard suppliers instead of marketplaces and intermediaries.

“It meant we should get into [aircraft component] manufacturing – that’s the way forward for our business. But we also knew it would require substantial capital investments,” Sanghavi said.

The founders took the plunge.

Jeh is making significant strides and currently develops aerostructures and aero-engine components. It has carved a niche in build-to-print assemblies (in this type of contract manufacturing, drawings and specifications are provided by clients), with expertise in high-precision drilling, coldworking processes and wire harness assembly. It also offers additional services, including painting, anodising and non-destructive testing (NDT). For context, NDT is a bunch of system evaluation and data collection methods for optimum safety and flawless maintenance.

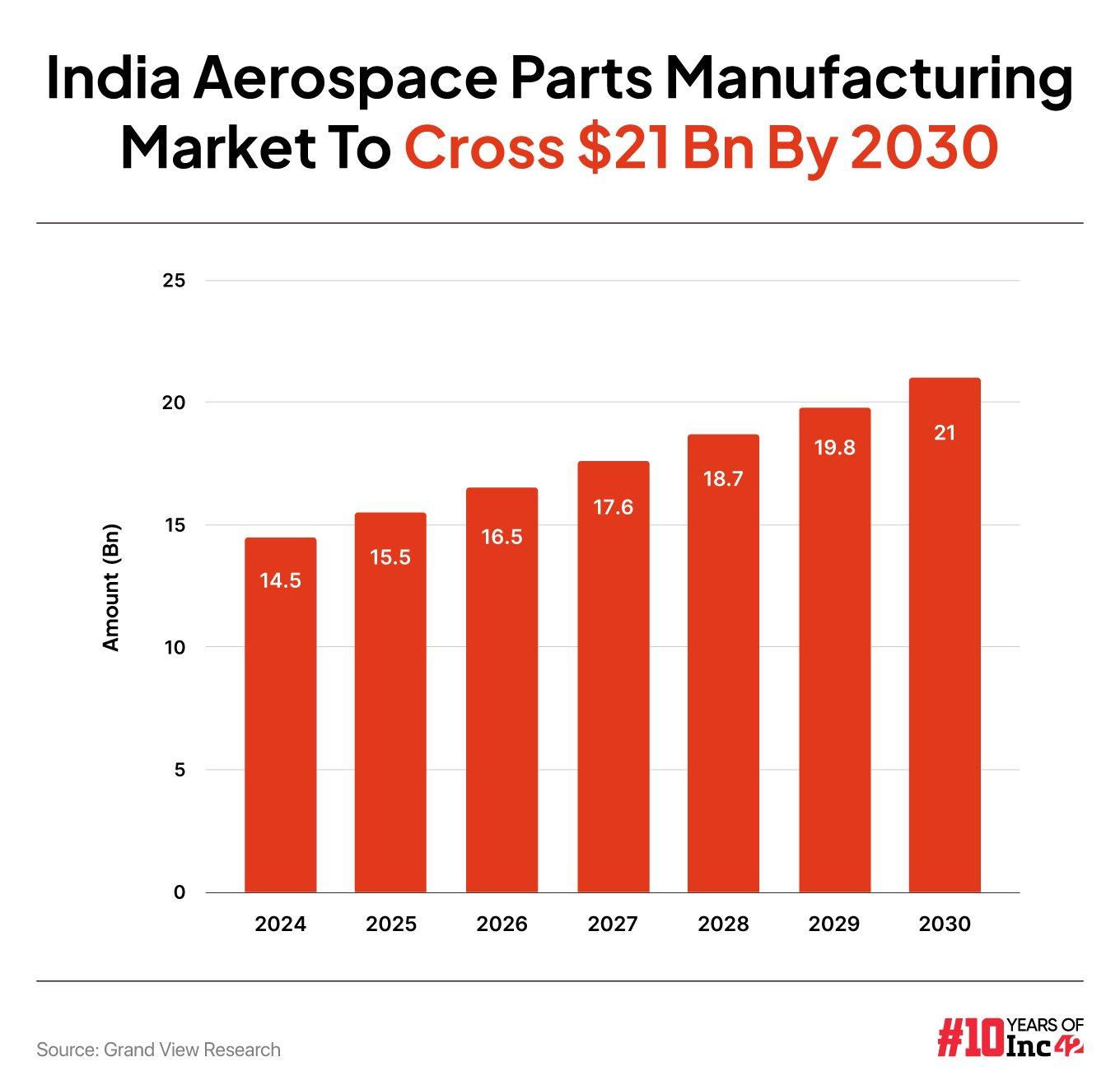

Although it is a pre-revenue startup at this point (Jeh did not earn any revenue in FY23 and did not disclose its FY24 financials), aerospace parts manufacturing (and the overall A&D space) is considered a sunrise sector in India, given the country’s strategic focus on cutting-edge technologies, critical defence equipment and rising air travel minus an overwhelming import dependency. A report by Grand View Research estimates the India market size to reach $21.5 Bn by 2030, from $13.6 Bn in 2023, at a CAGR of 6.8% between 2024 and 2030.

Therefore, it is not surprising that Sanghavi and Mudragalla are targeting an annual recurring revenue (ARR) of $20 Mn as early as FY25 and tapping into overseas markets to cater to global demand.

Initially, the founders were not too keen on funding and planned to remain bootstrapped. But they saw considerable investor interest and raised a seed round worth $2.75 Mn from General Catalyst and others in January 2024. Boeing India’s former president and MD, Pratyush Kumar, and Airbus India’s former CEO and MD, Dwarakanath Srinivasan, also participated in this round.

With this funding in place, Jeh is accelerating its plans to set up a full-fledged manufacturing hub in Telangana’s Kothur district, about 36 km from Hyderabad. Jeh opened the facility right after receiving the seed funding, but it is still in its initial phase.

According to the founders, this hub extends up to 1.6 Lakh sq. ft as the startup gears up to provide a full range of engineering, manufacturing and supply chain solutions to all OEMs and tooling companies in the A&D sector.

As its manufacturing unit is up and running, the startup is trying to onboard 10-12 big-ticket clients by 2025 to grow its business 50x. Jeh claims to be in advanced talks with multiple companies looking for robust suppliers.

Jeh Aerospace has already roped in a couple of clients, leveraging its strong ties in the US-India trade corridor. Among these is Vermont-based GS Precision, which tied up with Jeh for manufacturing aero-engine parts in May 2024.

From The House Of Tata To Startup Minting: How Founders Gave Wings To Jeh

As Sanghavi climbed the corporate ladder to become COO of the Tata-Boeing joint venture, he also helmed the Tata-Sikorsky JV, a collaboration between Tata Advanced Systems and US-based Sikorsky Aircraft Company. Meanwhile, Mudragalla played a crucial role in setting up the latter’s aero-engine capabilities, a business line now poised to manage a $1 Bn backlog.

Working for the iconic Tata group honed their professional skills and brought them recognition – a rich and satisfying experience. But they caught the entrepreneurship bug and longed to run their own business.

“A couple of black swan events in 2019-20 also gave us an opportunity,” said Sanghavi. “If you remember, there were some fatal air crashes,… like the Bek Air Fokker F-100 crash and the Ethiopian Airlines’ Flight 302. The entire industry was under the scanner until air travel reached a near standstill during the Covid-19 pandemic.”

He detailed how the pandemic disrupted air travel, compelling many seasoned manufacturers and component makers to shut shop. According to an OliverWyman report, first published in Forbes, top-tier aircraft manufacturers used to field calls from erstwhile healthy suppliers warning that the latter might be forced to close their doors because 40-50% of their business disappeared overnight.

The scenario reversed when the pandemic eased, and flight restrictions were lifted, but the heavy dent caused by the pandemic did not go away. Per a recent US GAO (Government Accountability Office) report, representatives from Boeing and Airbus said it had been challenging to meet their production targets since demand for new aircraft returned in 2021 as component manufacturers and raw material suppliers had difficulty filling orders.

In fact, Boeing says it can assemble a 737 in a matter of days once it has all the needed supplies at the final assembly facility, but it orders materials and components from suppliers months or years before they are required.

“As supply could not match the demand, aviation companies are now witnessing the biggest backlogs,” said Sanghavi. He also claimed that the state of flux in aircraft component manufacturing opened up a business opportunity north of $20 Bn.

Sensing a huge market opportunity, the founders set out to build Jeh Aerospace. They had no experience of building a manufacturing business from scratch, but their work at the Tata group’s aerospace wing stood them in good stead. However, the challenge here was different.

The salt-to-software conglomerate could succeed easily due to its unfettered access to advanced technologies, deep pockets and talent base. In contrast, Jeh started with little backing despite its founders’ professional skills and razor-sharp focus. So, building the startup required a significant shift towards building resources, although know-how and contacts helped.

What Works In Jeh’s Favour: The AI Edge, Quality & Cost Advantage

India’s aerospace sector is ripe for exponential growth, which means more and more players will be required for component manufacturing and innovation. The country’s growing prowess will also make it a go-to destination for global manufacturers.

Jeh might have been a pioneer in this space. However, it must compete with a growing number of players like Gopalan Aerospace, Kun Aerospace and many more, each one aiming to carve a niche and tap into a burgeoning overseas market. According to SkyQuest, the global aerospace parts manufacturing market size is poised to grow from $935.4 Bn in 2023 to $1,290.07 Bn by 2031, at a CAGR of 4.1% during the forecast period.

Of course, established OEMs will be the biggest contenders dominating this market, but Jeh is rapidly building its tech capabilities to stand out from the rest. In July 2024, it partnered with Blackstraw AI, an enterprise-grade AI solutions provider, to bolster its tech capabilities. The startup plans to develop and embed AI tools to optimise manufacturing processes, enhance supply chain efficiency and foster innovation through this alliance.

It is especially keen to automate complex manufacturing tasks to reduce production time and costs. It will also implement AI-powered quality control systems to detect anomalies and meet global quality standards.

According to Mudragalla, the startup’s competitive edge lies in tech-focussed talent base, competitive production cost and, more importantly, the trust it has gained within a short span. Jeh will cater to Tier I and II suppliers to grow its business. For context, Tier I suppliers work directly with OEMs and provide complete systems, while Tier II firms develop sub-assemblies for Tier I suppliers.

Jeh has a long-haul flight ahead, with little froth in the market after a harsh funding winter. Nevertheless, it has all the right components – from talent, technology and skills to government support and fast-growing global demand. Can it leverage India’s ascent as an emerging manufacturing hub to find a firm footing?

[Edited by Sanghamitra Mandal]

![[CITYPNG.COM]White Google Play PlayStore Logo – 1500×1500](https://startupnews.fyi/wp-content/uploads/2025/08/CITYPNG.COMWhite-Google-Play-PlayStore-Logo-1500x1500-1-630x630.png)